Dynamomter

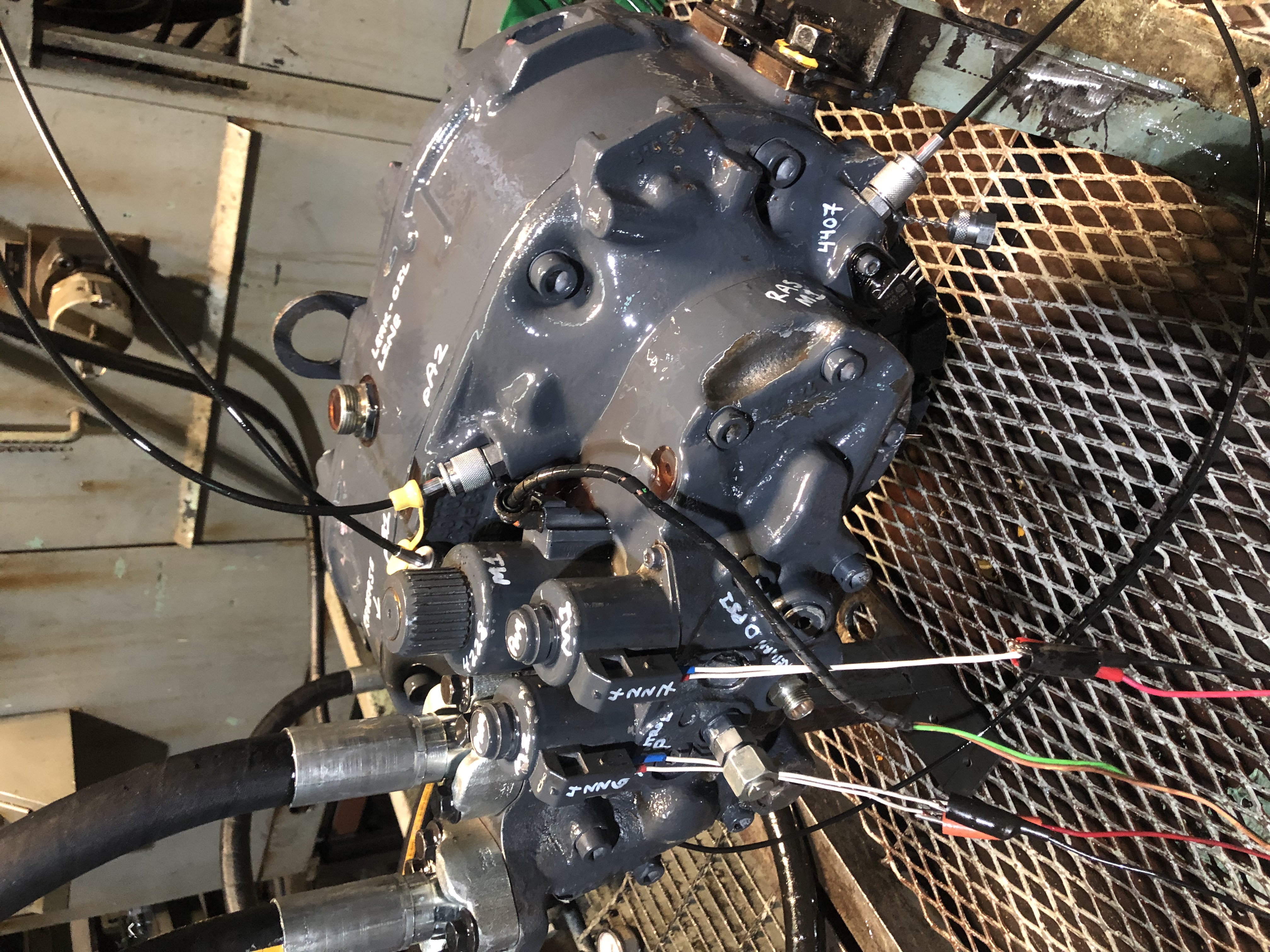

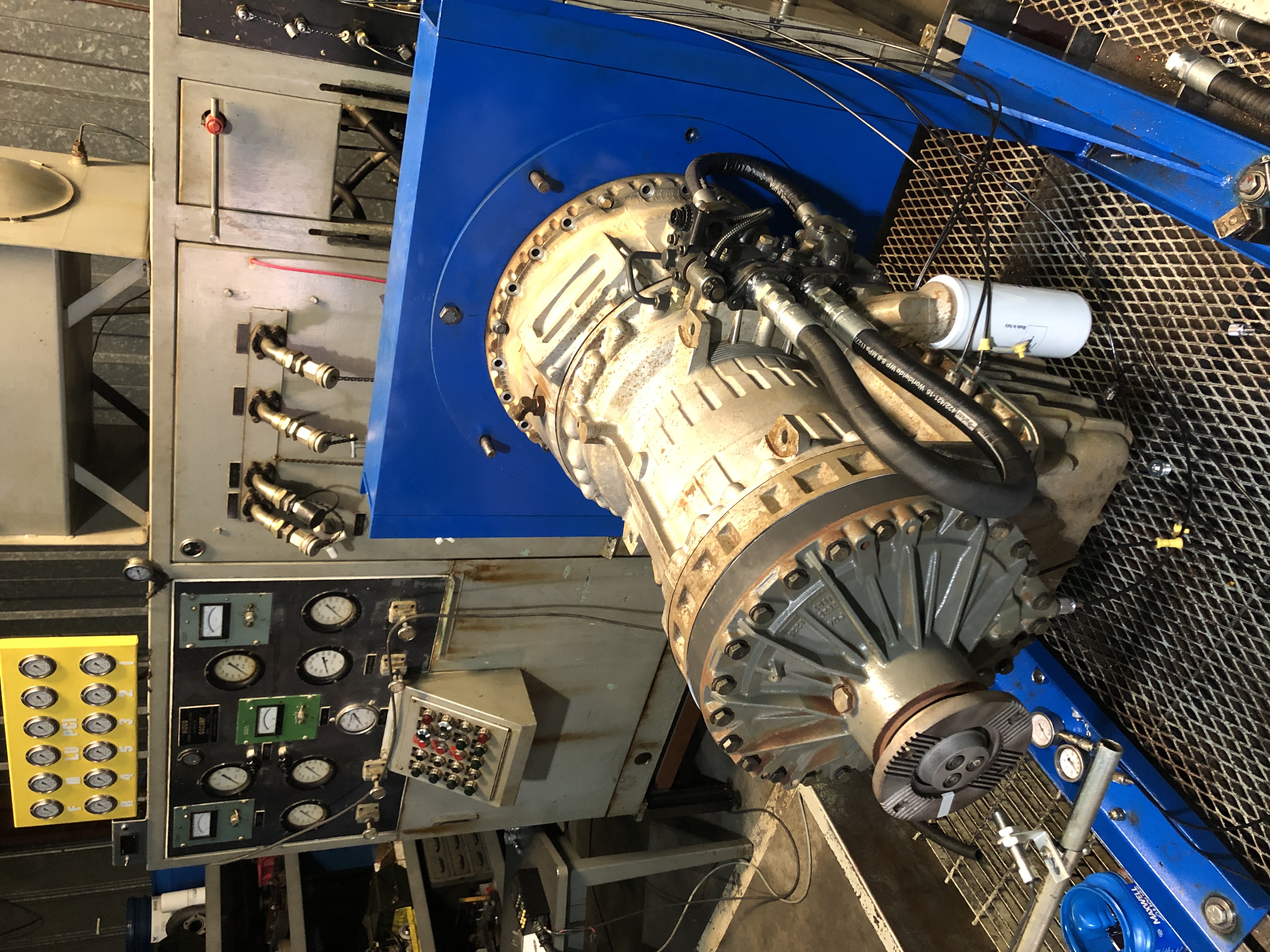

Testing on a dyno unit ensures that your component will work properly once installed in your machine. We also test components to rule out an issue before getting into costly repairs. Many problems can occur as components are changed in a piece of heavy equipment. This could be as simple as lines being hooked up improperly or being plugged, to shorts in wiring as harnesses have been pulled or removed. It is imperative that the components are tested so they can be ruled out if issues arise. Electrical issues are by far the most common problem we see when dyno testing units. The complexity of sensors and solenoids has grown with technology, along with the headaches they cause when they are not working properly. In the past main pressure and modulation was regulated with a mechanical valve (ball & spring), or spools and springs. Today pressures and modulation are regulated with Pulse Width Modulated Solenoid Valves. Running these units isn't enough, you have to get them up to operating temperature before you see a lot of the issues these solenoids can develop. As many of these solenoids are internal, the dyno is a great tool for discovering these issues and fixing them before they are installed in your machine.

We have all the templates for heavy off-road Volvo articulated haul trucks and Loaders. We also run many Caterpillar, Clark, Dana-Spicer, Euclid/Allison, and ZF transmissions. If you need a transmission tested give us a call! We will discuss